The collaboration between universities and industry partners drives local agricultural innovation by bridging the gap between academic research and practical, real-world application. Based on the sources, this process unfolds through several key mechanisms:

1. Access to Targeted Innovation Funding

Innovation is often sparked by government-led initiatives, such as the Kedaireka Innovation Fund. This program facilitates partnerships by providing the necessary financial support for university innovators to collaborate with industry partners or MSMEs (Micro, Small, and Medium Enterprises). For example, the partnership between Ahmad Dahlan University (UAD) and Pelindo allowed for the development of advanced technology specifically designed to support Agradaya, a local spice-producing MSME.

2. Solving Practical Industry Challenges

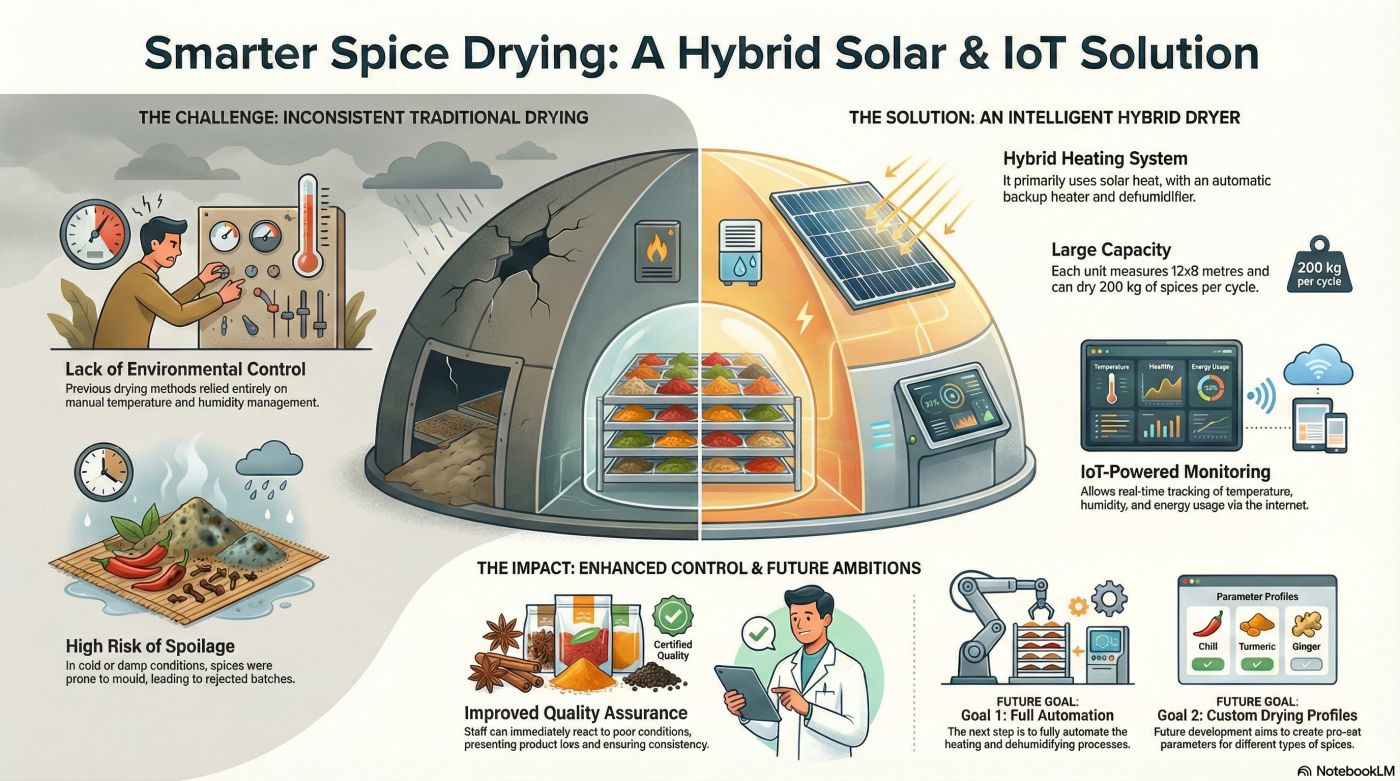

Industry partners provide the “real-world” problems that academic expertise can then solve. In the case of Agradaya, their previous drying methods relied on manual monitoring, which made them vulnerable to extreme weather; if the temperature was too low or humidity too high, it resulted in mould growth and rejected products. The university addressed this by implementing a Hybrid Solar Dome Dryer. This technology uses:

- Polycarbonate materials to trap solar heat.

- Hybrid heaters and dehumidifiers that can operate automatically when conditions are suboptimal.

- Solar power (PLTS), using solar panels and batteries to ensure energy efficiency and independence.

3. Integrating Advanced Technology (IoT)

A major driver of innovation in this collaboration is the integration of the Internet of Things (IoT). By applying IoT, parameters such as temperature, humidity, voltage, and energy consumption can be monitored in real-time via the internet. This allows farmers and industry partners to make data-driven decisions, such as manually activating heaters or maximizing exhaust fans when specific thresholds are met, ensuring “world-class” product quality.

4. Facilitating Continuous Improvement and Research

The collaboration creates a feedback loop that informs future research and development. The industry partner identifies specific areas where the current technology can be refined, such as:

- Improved automation for the heating process to reduce manual intervention.

- Commodity-specific settings, as different spices require different temperature and humidity parameters.

- Faster humidity control through potential additions of more fans or advanced dehumidifiers.

Ultimately, these collaborations aim to empower local farmers and enhance the independence and quality of national food products, ensuring that innovative works by “the nation’s children” have a direct impact on the community.